At Data Miners, we are thrilled to introduce our ground-breaking project that revolutionizes work order efficiency through advanced material tuning techniques. By optimizing task lists, creating consistent material profiles, and implementing proactive alarms, we eliminate the costly challenge of last-minute reschedules due to material unavailability, resulting in improved operational efficiency and significant cost savings.

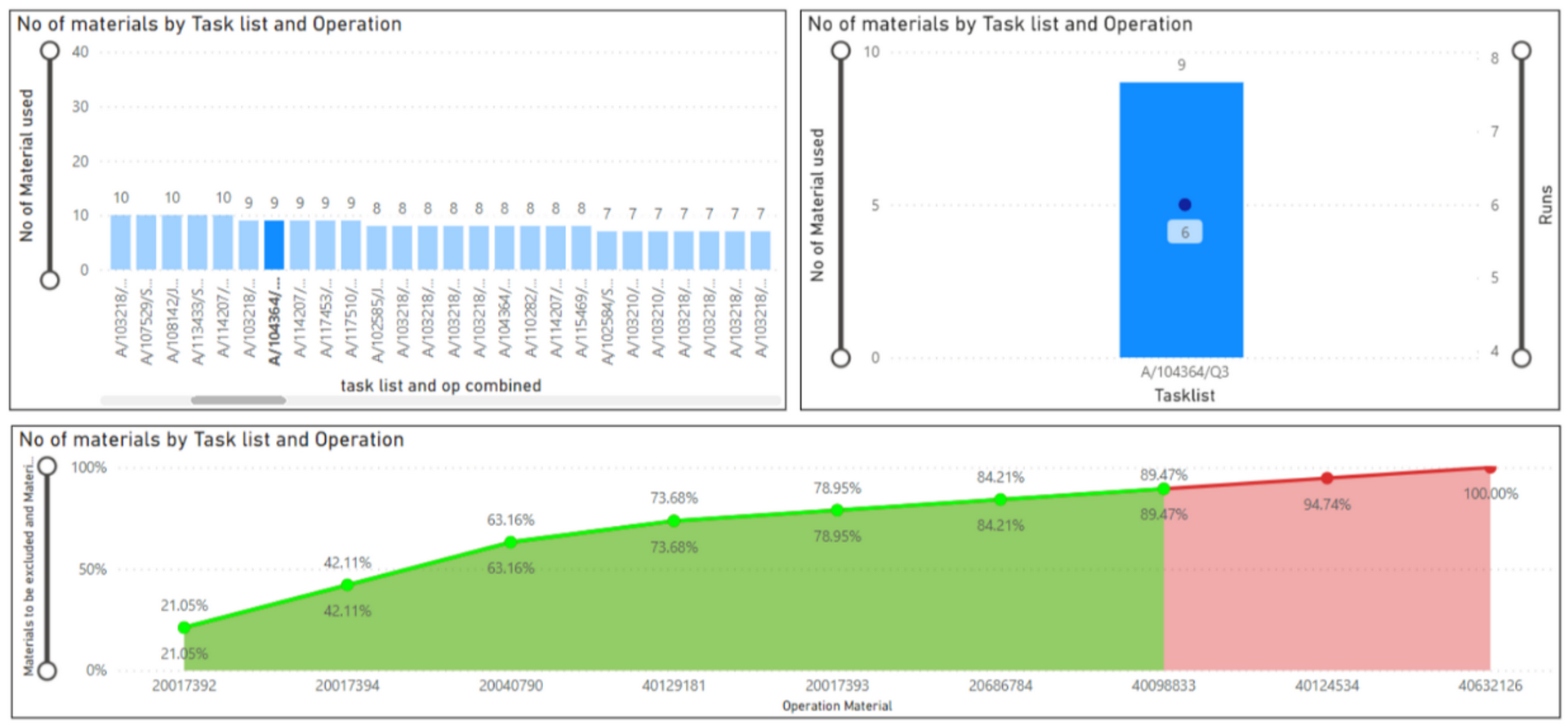

Our approach addresses the inconsistencies and ad-hoc nature of material planning within work order management. We understand the detrimental effects of frequent rescheduling, delays, and unnecessary expenses caused by inadequate material preparation. With our solution, we introduce a game-changing approach by profiling assets and establishing standardized material lists. This ensures that work orders are equipped with the right materials from the outset, eliminating the need for last-minute adjustments.

Furthermore, our solution leverages data-driven insights to deploy alarms for lead times, enabling proactive procurement when critical parts or materials are required for upcoming maintenance schedules. This foresight significantly reduces downtime, streamlines execution, and enhances overall work order efficiency.

The results of our back-testing are truly astounding. By utilizing the new material quantities and optimized profiles, our solution would have improved material planning accuracy by an impressive 35%. This means fewer instances of material unavailability, reduced rescheduling, and smoother execution of work orders. The analysis further revealed millions of dollars in potential savings on work orders that were previously rescheduled due to material unavailability at the site.

Moreover, our algorithm uncovered interesting insights into inventory management. While recommending a deflation of inventory to eliminate unnecessary costs, we also suggested inflating inventory for critical assets, ensuring their uninterrupted maintenance. This strategic balance resulted in an overall deflation of inventory, optimizing costs while maintaining operational resilience.

Currently, we are conducting a proof-of-concept (PoC) of our solution, and the preliminary findings are highly promising. Our solution demonstrates the potential to revolutionize material planning, reduce expenses, and enhance overall asset management for our clients.