Our innovative solution utilizes data science to transform preventative maintenance planning delivering remarkable results for organizations. By leveraging advanced analytics and predictive modelling, we optimize task completion hours and ensure task list consistency, leading to significant cost savings and improved operational efficiency.

Traditional planning often faces challenges with inconsistent task lists, resulting in manual adjustments and inefficiencies. Our solution eliminates these inconsistencies by proposing a fixed set of tasks for each list, saving valuable time for planners, and streamlining the planning process.

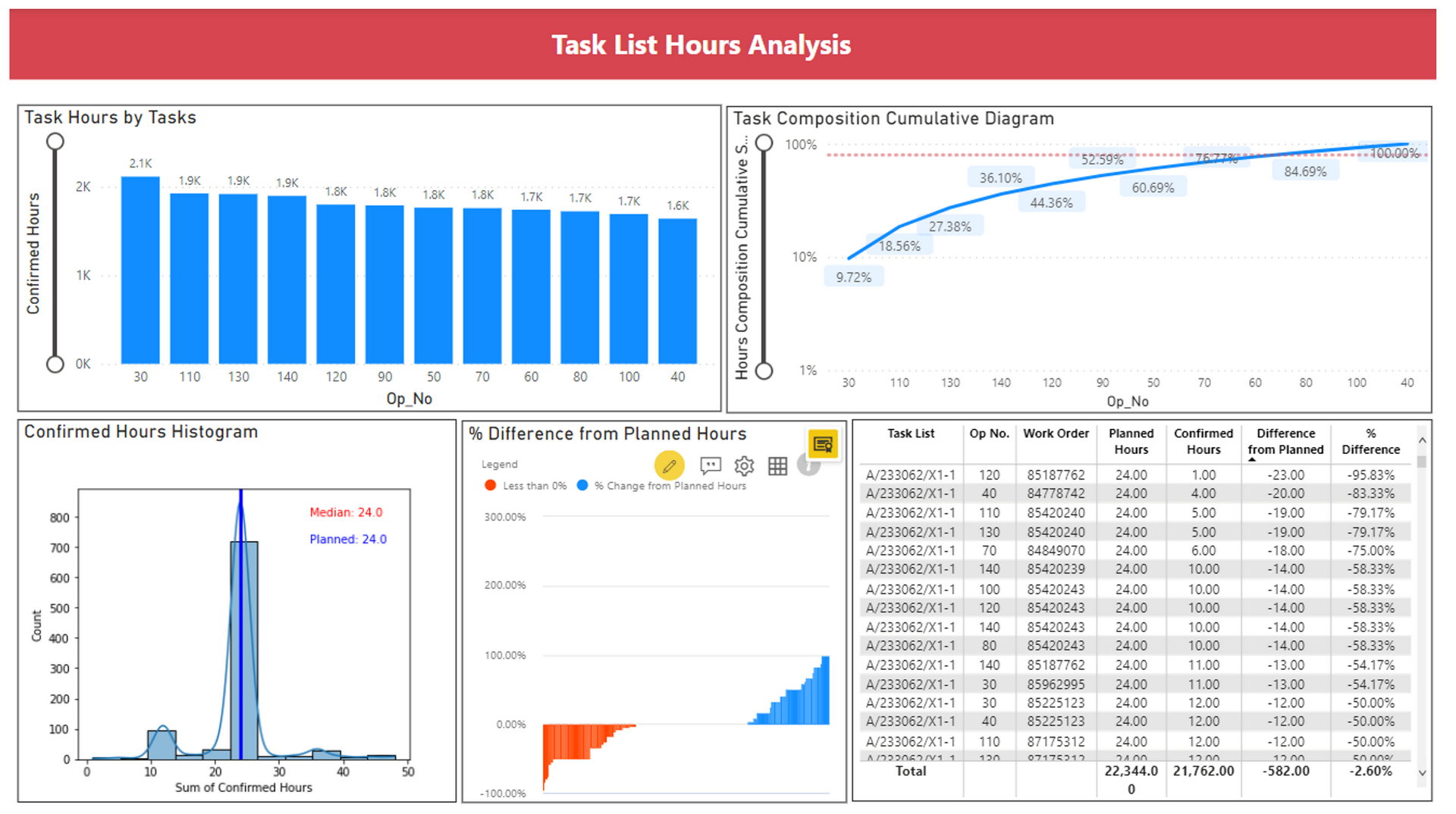

Through analysis of historical confirmed hours and machine learning models, we accurately predict the optimal hours required for each task within a work order. Our approach considers equipment type, maintenance complexity, and technician expertise, tailoring estimates to your organization's specific needs.

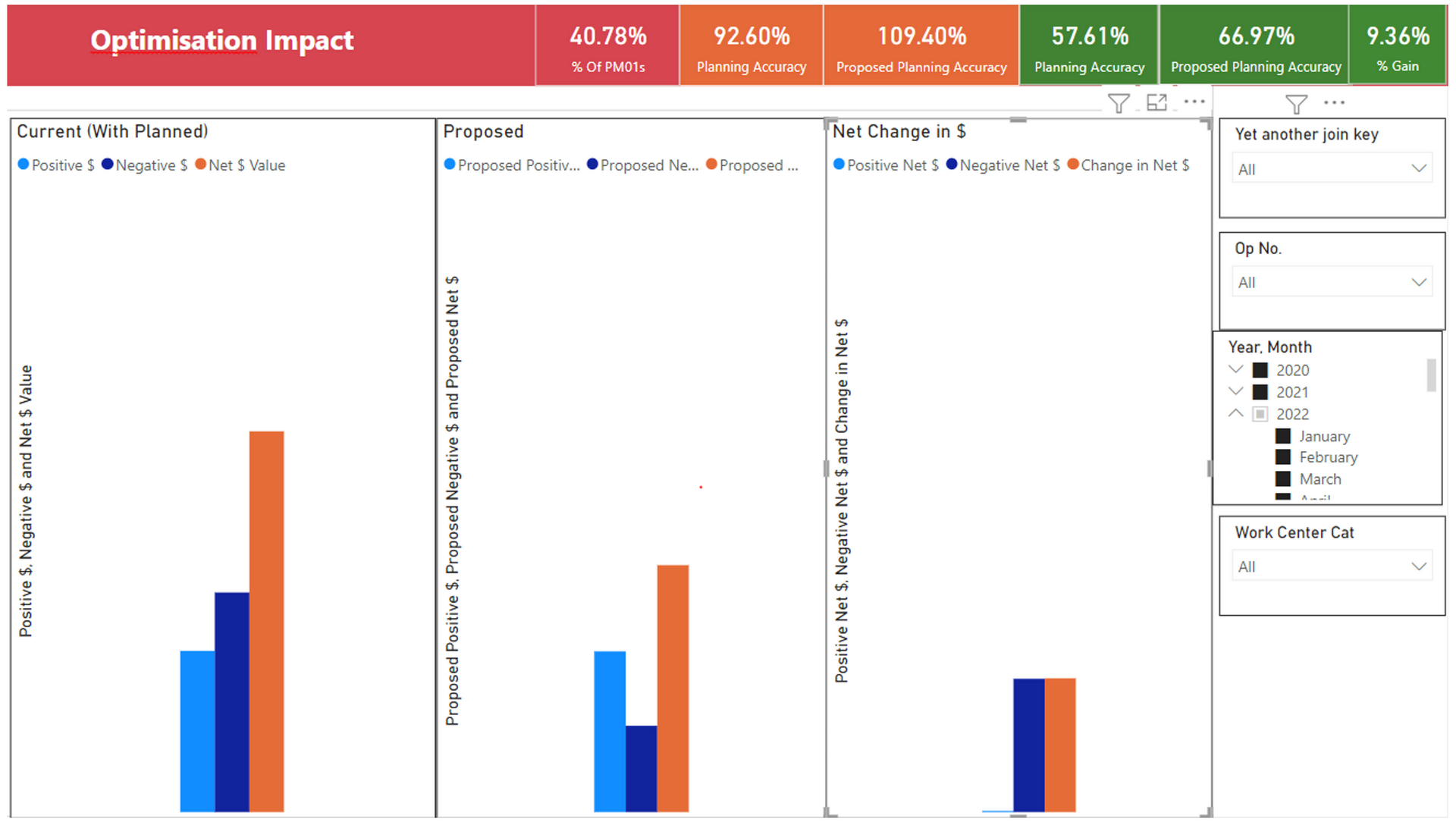

Back-testing revealed the potential for substantial cost savings, with millions of dollars identified through the implementation of optimized hours. Additionally, organizations experienced an impressive planning accuracy gain of approximately 15%.

A successful proof-of-concept (PoC) further validated our solution, showcasing a remarkable 13% improvement in planning accuracy. This success underscores the reliability and potential of our approach to revolutionize preventative maintenance planning.

By adopting our solution, you can optimize resource allocation, reduce costs, and streamline maintenance processes. Our automated task list adjustment feature eliminates the need for last-minute manual interventions, saving time and enhancing overall operational efficiency.