At Data Miners, we specialize in vibration analysis, a powerful technique that allows us to detect machine failures before they occur, saving organizations significant costs and preventing costly downtime. Our team of subject matter experts (SMEs) is highly trained in analyzing machine vibrations in both the time and frequency domains, employing various techniques to uncover hidden insights and predict potential failures.

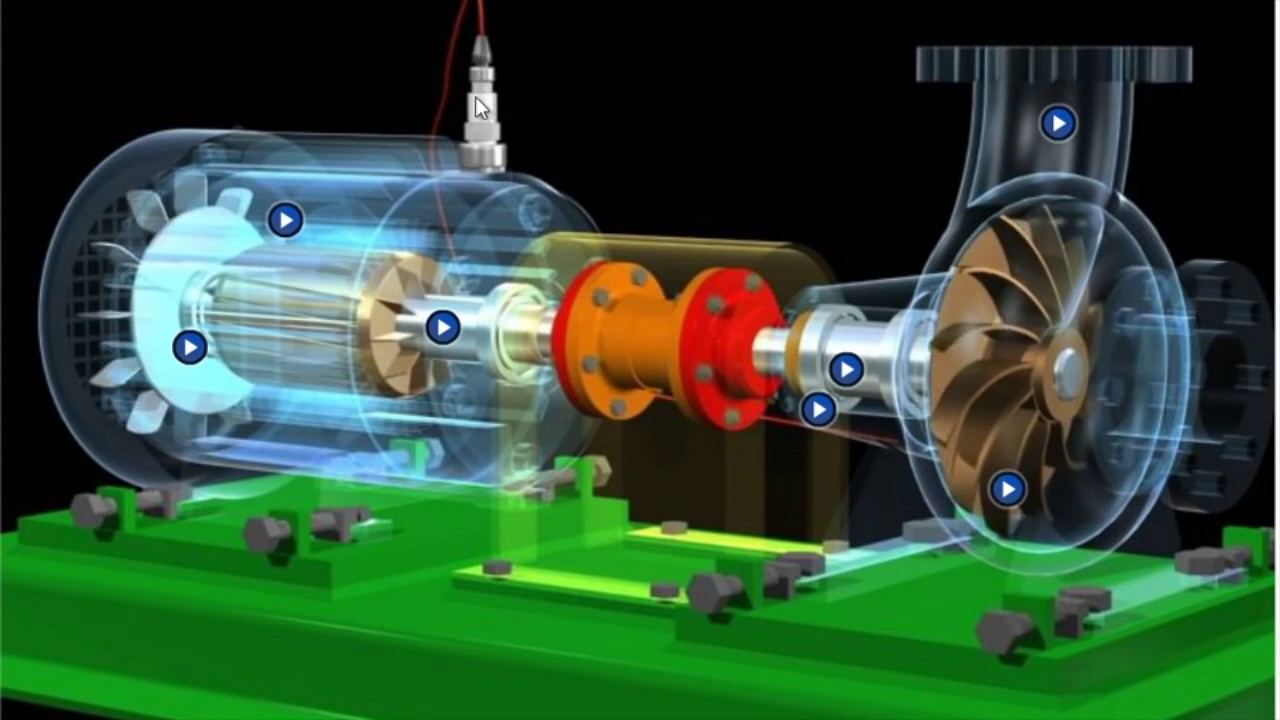

In the time domain, we analyze the raw vibration signals captured from machines using sensors or accelerometers. One technique we employ is time waveform analysis, which involves examining the amplitude, shape, and frequency content of the vibration signals over time. By analyzing trends and patterns, we can identify abnormal vibrations that may indicate underlying issues or impending failures. Additionally, we utilize statistical analysis techniques such as root mean square (RMS) and peak detection to quantify the severity of vibrations and establish baseline levels for comparison.

In the frequency domain, we employ Fourier Transform-based techniques to transform the time-domain vibration signals into frequency spectra. One commonly used technique is Fast Fourier Transform (FFT), which enables us to analyze the frequency components present in the vibration signals. By studying the frequency spectrum, we can identify specific frequencies or frequency ranges associated with machine faults, such as bearing defects, imbalance, misalignment, or looseness. Spectral analysis techniques, such as peak detection, sideband analysis, and harmonic analysis, help us pinpoint the underlying causes of vibration abnormalities.

Another powerful technique we utilize is the envelope analysis, which focuses on capturing the modulation characteristics of the vibration signal. By extracting the envelope of the vibration signal, we can identify low-frequency variations or amplitude modulations that are indicative of specific faults, such as gear or bearing faults. This technique enhances our ability to detect early-stage failures and predict potential issues before they escalate.

At Data Miners, we combine these advanced vibration analysis techniques with our domain expertise and extensive industry knowledge. We work closely with organizations to develop customized vibration monitoring programs, establish baseline vibration levels, and set up condition monitoring systems. By regularly analyzing machine vibrations, tracking trends, and applying predictive modeling, we help organizations proactively identify and mitigate potential failures, ultimately improving equipment reliability and reducing costly downtime.

Our vibration analysis services have been successfully applied across various industries, including manufacturing, power generation, oil and gas, and transportation. We have helped organizations save significant costs by detecting impending failures early, enabling them to take preventive maintenance actions and avoid unplanned shutdowns.

Trust Data Miners to be your partner in leveraging vibration analysis to optimize equipment reliability, minimize downtime, and maximize cost savings. Our expertise, combined with state-of-the-art techniques, ensures that your machinery remains in optimal condition, enabling your business to operate smoothly and efficiently.